SACHIN SHANBHAG |

1. Crystallization of Copolymers from Solutions

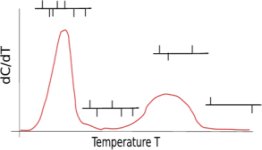

Copolymerization is used to tune the properties of man-made plastics, for example to regulate crystallinity, to enhance mechanical properties, and to expand the temperature performance window by incorporating one or more comonomers into a homopolymer chain. These properties are governed by the details of the chain microstructure, i.e. distribution of comonomers and the molecular weight. These distributions are crucial to establish structure-property relationships, and to monitor product quality. The analytical techniques commonly used to characterize the chemical composition distribution (CCD) of semicrystalline binary ethylene/olefin copolymers, such as Crystaf and solution DSC, are based on the relationship between the thermodynamic driving force for crystallization and the branching content. In these copolymers the longer the ethylene sequences between branches, the more stable the polymer is in solution. The length of the segment between branches decreases as comonomer content increases. Consequently, copolymer chains with more short chain branches crystallize at lower temperatures, forming thinner lamellae and less perfect crystallites.

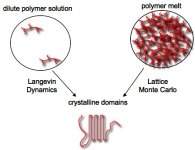

Copolymerization is used to tune the properties of man-made plastics, for example to regulate crystallinity, to enhance mechanical properties, and to expand the temperature performance window by incorporating one or more comonomers into a homopolymer chain. These properties are governed by the details of the chain microstructure, i.e. distribution of comonomers and the molecular weight. These distributions are crucial to establish structure-property relationships, and to monitor product quality. The analytical techniques commonly used to characterize the chemical composition distribution (CCD) of semicrystalline binary ethylene/olefin copolymers, such as Crystaf and solution DSC, are based on the relationship between the thermodynamic driving force for crystallization and the branching content. In these copolymers the longer the ethylene sequences between branches, the more stable the polymer is in solution. The length of the segment between branches decreases as comonomer content increases. Consequently, copolymer chains with more short chain branches crystallize at lower temperatures, forming thinner lamellae and less perfect crystallites.  Thus, our strategy is two-pronged. At an engineering level we seek to build mechanistic models to predict Crystaf curves from the chemical composition, and vice versa. There are a number of unsolved problems in the theory of nonisothermal crystallization of copolymers from solutions. At the fundamental level we seek to get a glimpse into these processes using Langevin dynamics and kinetic Monte Carlo models.

Thus, our strategy is two-pronged. At an engineering level we seek to build mechanistic models to predict Crystaf curves from the chemical composition, and vice versa. There are a number of unsolved problems in the theory of nonisothermal crystallization of copolymers from solutions. At the fundamental level we seek to get a glimpse into these processes using Langevin dynamics and kinetic Monte Carlo models. |

2. Cyclic Polymers

Concentrated solutions of ring or cyclic polymers (CPs), which lack chain ends, are scientifically intriguing, since they defy a simple description in terms of the tube model which has been used rather successfully to describe the properties of linear and branched polymers. My focus is the on the statics and dynamics of blends of cyclic and linear polymers. These blend systems are important for two reasons: (i) most experimental data on pure CPs are, in fact, data on cyclic-linear blends (CLB), due to contamination or limitations of purification methods, and (ii) the dynamics of such CLBs, are extraordinarily sensitive to the concentration of linear polymers, as demonstrated by the linear viscoelastic and self-diffusion studies. These studies indicate a dramatic change in the mobilty of CPs that is, both, unexpected and unexplained, and might supply deep insights into entangled polymer dynamics. Recent simulations seem to indicate that CLBs might be ideal systems to unravel the controversial process of constraint release.

Concentrated solutions of ring or cyclic polymers (CPs), which lack chain ends, are scientifically intriguing, since they defy a simple description in terms of the tube model which has been used rather successfully to describe the properties of linear and branched polymers. My focus is the on the statics and dynamics of blends of cyclic and linear polymers. These blend systems are important for two reasons: (i) most experimental data on pure CPs are, in fact, data on cyclic-linear blends (CLB), due to contamination or limitations of purification methods, and (ii) the dynamics of such CLBs, are extraordinarily sensitive to the concentration of linear polymers, as demonstrated by the linear viscoelastic and self-diffusion studies. These studies indicate a dramatic change in the mobilty of CPs that is, both, unexpected and unexplained, and might supply deep insights into entangled polymer dynamics. Recent simulations seem to indicate that CLBs might be ideal systems to unravel the controversial process of constraint release. A recent presentation on some of this material at ICR 2008 (pdf) |

3. Microscopic Simulations of Concentrated Polymer Solutions and Melts

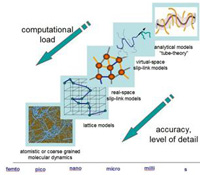

The wide separation of dynamical timescales, ranging from the order of pico-seconds for

inter-atomic oscillations, to the order of hours for phenomena of greatest relevance to polymer

processing, makes it practically impossible to describe the complete dynamics of concentrated polymer

solutions and melts using a single modeling methodology (like molecular dynamics, for example).

Therefore, a number of coarse-grained microscopic and mesoscopic models have been developed in which

all the action occurring at fast local levels is smeared out, and attention is focused only on slower

modes of motion which control properties such as viscosity.

The wide separation of dynamical timescales, ranging from the order of pico-seconds for

inter-atomic oscillations, to the order of hours for phenomena of greatest relevance to polymer

processing, makes it practically impossible to describe the complete dynamics of concentrated polymer

solutions and melts using a single modeling methodology (like molecular dynamics, for example).

Therefore, a number of coarse-grained microscopic and mesoscopic models have been developed in which

all the action occurring at fast local levels is smeared out, and attention is focused only on slower

modes of motion which control properties such as viscosity.  In order to encompass the broad spectrum of timescales (about 10 decades), we are interested in developing an

"overlapping" multiscale modeling strategy such as that outlined in the figure above. "Detailed" models include

simulation methods such molecular dynamics and the bond-fluctuation lattice models which are coarse-grained at

the Kuhn-step level (~1 nm). In general, these detailed simulations can be used to question, justify, or reject

certain assumptions made in coarse-grained models, and progressively improve these coarse-grained models. We are

particularly interested in how sub-chain level mechanisms can be interpreted and recast into the parameters describing

the mean-field "tube model". We expect the cross-talk between various levels of modeling to open up, and shape future

directions of inquiry.

In order to encompass the broad spectrum of timescales (about 10 decades), we are interested in developing an

"overlapping" multiscale modeling strategy such as that outlined in the figure above. "Detailed" models include

simulation methods such molecular dynamics and the bond-fluctuation lattice models which are coarse-grained at

the Kuhn-step level (~1 nm). In general, these detailed simulations can be used to question, justify, or reject

certain assumptions made in coarse-grained models, and progressively improve these coarse-grained models. We are

particularly interested in how sub-chain level mechanisms can be interpreted and recast into the parameters describing

the mean-field "tube model". We expect the cross-talk between various levels of modeling to open up, and shape future

directions of inquiry. A presentation on some of this material at SoR 2007 (pdf) |

4. Rheology of Branched Polymer Melts

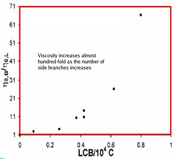

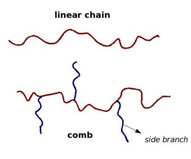

The rheological responses of linear chains, and "comb"-like molecules,

with long side chains along a linear backbone, are dramatically

different. For example, a minute degree of long-chain branching (LCB),

of the order of one side branch per 10,000 backbone carbon atoms, can

jack up the zero-shear viscosity of a linear chain by a factor of 100.

At the same time, LCB endows the polymer melt with desirable processing

properties such as shear thinning (thus low energy during process such

as molding and extrusion) and strain hardening (thus, they resist tear

during film blowing operations). Thanks to advances in

metallocene-based catalyst technology, LCB in polyolefins can be

administered and controlled to an unprecedented degree.

The rheological responses of linear chains, and "comb"-like molecules,

with long side chains along a linear backbone, are dramatically

different. For example, a minute degree of long-chain branching (LCB),

of the order of one side branch per 10,000 backbone carbon atoms, can

jack up the zero-shear viscosity of a linear chain by a factor of 100.

At the same time, LCB endows the polymer melt with desirable processing

properties such as shear thinning (thus low energy during process such

as molding and extrusion) and strain hardening (thus, they resist tear

during film blowing operations). Thanks to advances in

metallocene-based catalyst technology, LCB in polyolefins can be

administered and controlled to an unprecedented degree.  The threshold of conventional methods of chemical analysis like

spectroscopy and chromato-graphy in detecting sparse structural

details, like low concentrations of LCB, is far below a level that can

be considered adequate from an industrial perspective. The sensitivity

of rheology to molecular architecture and branching details has spawned

the notion of analytical rheology - the idea that linear viscoelastic

measurements can be used to probe the underlying molecular structure of

polymers. Work in this area attempts to build, primarily, upon the

standard tube theory for polymer melts. To complement theoretical work,

we also use mesoscopic simulation models, such as the slip link model

which is coarse-grained at the level of the "tube" diameter (a few

nanometers in melts). Linear viscoelastic data on a wide variety of

linear and branched polymer may be downloaded in the form of a

tar-zipped file tar-zipped file.

The threshold of conventional methods of chemical analysis like

spectroscopy and chromato-graphy in detecting sparse structural

details, like low concentrations of LCB, is far below a level that can

be considered adequate from an industrial perspective. The sensitivity

of rheology to molecular architecture and branching details has spawned

the notion of analytical rheology - the idea that linear viscoelastic

measurements can be used to probe the underlying molecular structure of

polymers. Work in this area attempts to build, primarily, upon the

standard tube theory for polymer melts. To complement theoretical work,

we also use mesoscopic simulation models, such as the slip link model

which is coarse-grained at the level of the "tube" diameter (a few

nanometers in melts). Linear viscoelastic data on a wide variety of

linear and branched polymer may be downloaded in the form of a

tar-zipped file tar-zipped file.

A presentation on some of this material at ACS 2006 (pdf) |

5. Modeling for Tissue Engineering Applications

Coaxing cells to produce functional tissue requires their cultivation and organization on 3D substrates, or scaffolds.

These scaffolds act as a surrogate for the extra-cellular matrix found in the human body. A wide range of materials and

manufacturing methods for the synthesis of 3D scaffolds have been developed. However, the development of scaffolds is beset

with a variety of challenges, including tissue ingrowth that is limited to the exterior of the scaffold due to insuffcient

nutrient and product transport, and loss of cellular phenotype due to improper cell-matrix, cell-cell interaction and

signaling.

Coaxing cells to produce functional tissue requires their cultivation and organization on 3D substrates, or scaffolds.

These scaffolds act as a surrogate for the extra-cellular matrix found in the human body. A wide range of materials and

manufacturing methods for the synthesis of 3D scaffolds have been developed. However, the development of scaffolds is beset

with a variety of challenges, including tissue ingrowth that is limited to the exterior of the scaffold due to insuffcient

nutrient and product transport, and loss of cellular phenotype due to improper cell-matrix, cell-cell interaction and

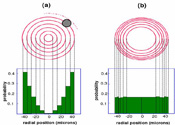

signaling.  Recently, highly uniform and organized tissue engineering scaffolds

possessing inverted-colloidal crystal (ICC) geometry, which are

inexpensive to manufacture and do not suffer from material constraints,

have been developed. Due to the regularity of these ICC scaffolds,

computational modeling functions as an important tool to explore the

vast available design space and to develop novel assays. For example,

in the past we have use borrowed Langevin dynamics (widely used in the

polymer and colloids literature) to characterize the transport of

nutrients/metabolic products through the porous ICC scaffolds, and to

quantify the extent of cell-matrix interaction and cell-cell

interactions. These studies have been used to optimize scaffold

geometry for particular cell lines, and have been validated

experimentally.

Recently, highly uniform and organized tissue engineering scaffolds

possessing inverted-colloidal crystal (ICC) geometry, which are

inexpensive to manufacture and do not suffer from material constraints,

have been developed. Due to the regularity of these ICC scaffolds,

computational modeling functions as an important tool to explore the

vast available design space and to develop novel assays. For example,

in the past we have use borrowed Langevin dynamics (widely used in the

polymer and colloids literature) to characterize the transport of

nutrients/metabolic products through the porous ICC scaffolds, and to

quantify the extent of cell-matrix interaction and cell-cell

interactions. These studies have been used to optimize scaffold

geometry for particular cell lines, and have been validated

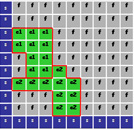

experimentally. Currently, we are trying to develop models that reflect some the

complexity and richness inherent in biological systems. For instance,

cells have anisotropic shapes and cell-cell and cell-matrix

interactions are usually highly specific. To incorporate these

processes, current and future research is aimed on developing

mesoscopic cellular automata and agent-based models.

Currently, we are trying to develop models that reflect some the

complexity and richness inherent in biological systems. For instance,

cells have anisotropic shapes and cell-cell and cell-matrix

interactions are usually highly specific. To incorporate these

processes, current and future research is aimed on developing

mesoscopic cellular automata and agent-based models. |

6. Modeling for Nanotechnology Applications

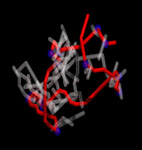

Back to Top In the past few decades, substantial progress has been made in

describing transport and quantum mechanical phenomena in nanocrystals

(NCs). As a next step, one must consider the organization or

integration of these NCs into optical or electronic devices. This

inevitably requires us to understand the nature and magnitude of

inter-particle interactions, since these very forces govern and dictate

their "self-assembly" properties, interactions with other nanoscale

entities, and methods of manufacturing. Dipole moment is one such

fundamental force, and in the past, we have examined the origin of

large anomalous dipole moment (~50-100 debye) in centero-symmetric

cubic nanocrystals. The energy associated with this polarity can

overcome random thermal fluctuations, and regulate interactions with

other nanoscale species such as proteins, as well as influence the

thermodynamics of charge-transfer processes.

In the past few decades, substantial progress has been made in

describing transport and quantum mechanical phenomena in nanocrystals

(NCs). As a next step, one must consider the organization or

integration of these NCs into optical or electronic devices. This

inevitably requires us to understand the nature and magnitude of

inter-particle interactions, since these very forces govern and dictate

their "self-assembly" properties, interactions with other nanoscale

entities, and methods of manufacturing. Dipole moment is one such

fundamental force, and in the past, we have examined the origin of

large anomalous dipole moment (~50-100 debye) in centero-symmetric

cubic nanocrystals. The energy associated with this polarity can

overcome random thermal fluctuations, and regulate interactions with

other nanoscale species such as proteins, as well as influence the

thermodynamics of charge-transfer processes.We have also examined the kinetics of unusual higher order structures such as checkmarks starting from Tellurium nanorods, using Brownian dynamics simulations. In general, such simulations, when used as a tool-kit in conjunction with synthesis, can be used to explore the available design space to suggest and exploit synthetic routes that might not be immediately obvious. |

© 2008 Sachin Shanbhag

Last Modified: 10/01/2008

Last Modified: 10/01/2008